Products

Ceramics | Metal | Special solutions

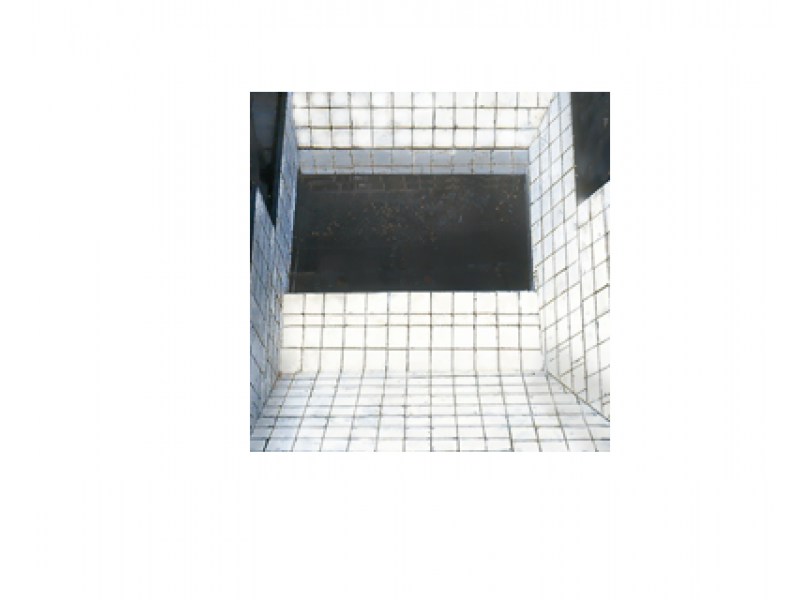

Cast basalt ABRESIST

Basalt is a volcanic rock with high density and uniform mineral structure. Its hardness makes it the perfect raw material for the mineral wear protection products used worldwide under the ABRESIST brand name. Cast basalt ABRESIST reliably protects plant components such as scale chutes, marl funnels, or coke bunkers in the iron and steel industry or pipelines, e.g. fly ash lines in thermal power plants, against frictional wear.

Features:

- Very hard and smooth surface for good flow properties

- Corrosion resistant

- Applicable in chemically demanding environments

- Food safe (FDA approved)

- Application temperature max. 350 °C

- Cylinder inside diameter from 40 – 525 mm

Cast basalt ABRESIST

Zirconia alumina wear protection with high temperature and abrasion resistance

The cast ceramic material KALCOR has proven itself in the lining of plant components in which high temperatures and temperature changes occur in addition to extreme wear stress, e.g. in chutes for hot sinter or clinker, in hot gas lines or in dust removal cyclones and separators.

Features:

- Very hard and wear resistant

- Corrosion resistant

- Applicable in chemically demanding environments

- Application temperature max. 1200 °C

- Thin wall thicknesses for cylinders from 12 mm

- Good resistance to temperature changes

- Wide geometry spectrum

- Cylinders in diameter from 50 – 500 mm

- Asymmetrical cross sections possible for pipe bends

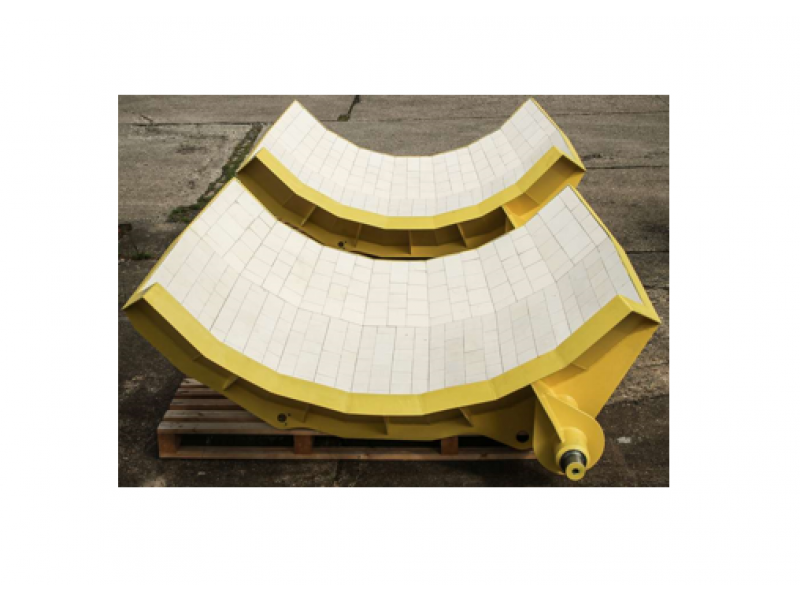

Alumina ceramic KALOCER

Ceramic wear protection for plant components subject to extreme wear and temperature stresses

The material oxide ceramics KALOCER made of more than 90% aluminum oxide is produced as plates, fittings and cylinders. KALOCER is ideal for plant components with extreme frictional wear. Linings with material thicknesses from 1.5 mm thus also open up use in confined conditions. KALOCER is particularly suitable for lining separators, bunkers, chutes, belt transfers, concrete mixers or cyclones in all industries. With KALIMPACT as a hard-soff rubber compound, high impact resistance is also provided.

Features:

KALIMPACT

- High abrasion resistance and smooth surfaces

- Corrosion resistant

- Applicable in chemically demanding environments

- Food safe

- As a hard rubber compound KALIMPACT additionally high impact strength

- Easy adaptation to geometrically difficult surfaces

- Application temperature max.1200 °C (depending on assembly conditions)

- Thin wall thicknesses from 1.5 mm

- Weight saving solution

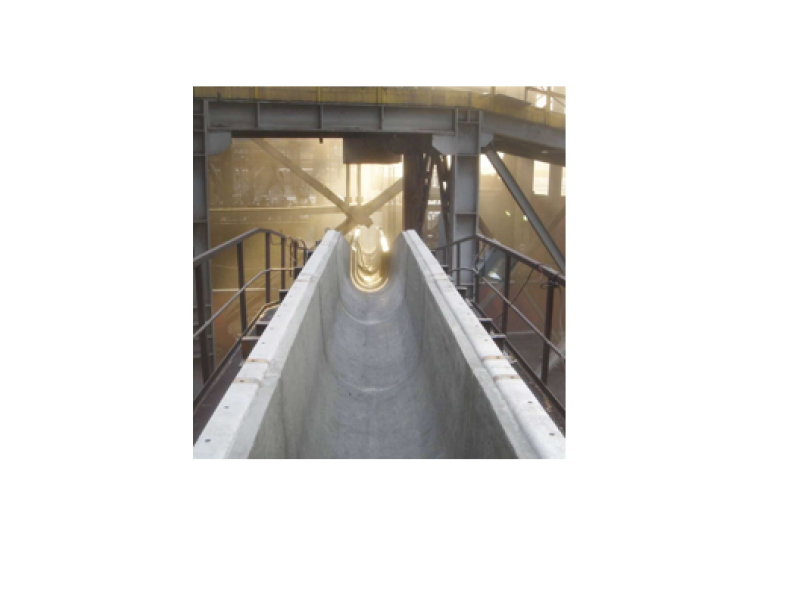

Hard compound KALCRET

Trowelable, sprayable or castable hard compound for plant components and piping systems

The hard compound KALCRET combines excellent wear protection properties with easy handling. Mineral hard materials serve as a basis. The particular advantage of all compounds is their flexibility in practice. Large areas are coated quickly and safely, so that plant availability is restored in a short time.

KALCRET is suitable for lining plant components and pipe systems, in power plants, in the steel and cement industries, and in waste incineration plants. Examples are pipe bends of pulverized coal lines, swirlers for dedusting blast furnace gases in steel mills, wind boxes and classifier linings in cement grinding.

Features:

- Filler, pourable and sprayable wear protection for jointless linings

- Large area and jointless lining

- Simple lining of geometrically difficult surfaces

- Variable layer thickness structure

- Application temperature max. 1200 °C

- Load capacity already after 24 hours

- Very well combinable with all other materials

- Simple repairs possible

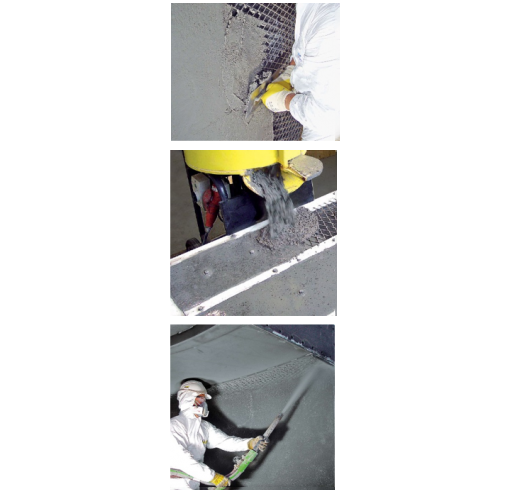

Application of KALCRET

Ways to apply KALCRET:

- Filler

- Casting

- Syringes

Hard ceramic KALCERAM

Abrasion-resistant sliding conveyor with high friction wear resistance

KALCERAM is an abrasion-resistant hard ceramic with good sliding properties. KALCERAM is the most economical material for lining plant components which, in addition to protection against frictional wear, require good sliding properties at elevated temperatures. The material is particularly suitable for lining coal bunkers, chutes and flumes in coking plants, bag loading chutes in cement plants, and cyclones, separators and classifiers.

Features:

- Good sliding properties and friction wear resistance

- Good temperature resistance

- Slabs or stones cut to size

Cast basalt ABRESIST

Hard overlay welding for high impact and wear resistance

KALMETALL is a metallic material produced by applying a hard overlay weld to steel sheet. As a manufacturer, we can specifically control the properties of hardfacing by changing the filler metals and adjust them precisely to the needs of the application. The plates produced by Kalenborn are characterized by excellent wear and impact resistance. As rubber compound KALIMPACT is possible high reduction of noise and vibration. These properties open up a wide range of applications for KALMETALL in numerous industrial plants.

Typical applications include: Screw conveyors, fan housings, cyclones and classifiers, mixer linings, piping components, screens, troughs and conveying channels

Features:

- KALIMPACT

- High wear and impact resistance

- Standard thickness of the base material from 5 mm

- Thickness of buildup welding 3 – 18 mm

- Application temperature max. 750 °C

- Wear and impact resistance as well as temperature resistance

- Alloy dependence selectable

- Complete lining systems from build-up welded sheets for existing steel structures

- Self-supporting structures with hard overlay welding

- Components ready to be installed according to customer specifications

- Combinations of ceramic and metallic materials for wear-optimized design with high cost-effectiveness

- As rubber compound KALIMPACT additionally reduces noise and vibrations

KALIMPAKT – formerly KERAFLEX

Hard rubber compound for heavy impact and friction wear

KALIMPACT as a hard rubber composite is used in particular when high impact loads occur in conjunction with heavy abrasion. The wear protection is vulcanized in rubber.

KALIMPACT consists of either the fused cast basalt ABRESIST, the oxide ceramic KALOCERorthe hardfacing KALMETALL, depending on the requirements for friction wear and impact strength in the composite system.

Standard sizes or elements adapted to the previous fastening systems, everything is feasible. In this way, the KALIMPACT system is designed to suit the respective application, thus providing the best cost/benefit factor for the user.

Not to be neglected is also the noise-reducing effect, which has been proven to be up to half of the perceived volume. Operators of plant components near such stressed employees or those of open pit mines and quarries near residential areas are likely to be familiar with this issue.

KALIMPACT KALOCER:

- Mosaic mats

- Low impact energy

- flat impact angle

- wear resistant against abrasion

- Adaptable to convex and concave shapes

- Thin wall thicknesses

- easy to cut

- adhesive

- Noise reducing

KALIMPACT KALOCER:

- Rectangles

- moderate impact energy

- flat impact angle

- excellent wear resistance against abrasion

- Mechanical or magnetic mounting

- Noise reducing

KALIMPACT KALOCER:

- Squares

- Very high impact energy

- steep impact angle

- very wear resistant against abrasion

- Mechanical or magnetic mounting

- Noise reducing

KALIMPACT ABRESIST:

- Plates

- Low impact energy

- flat impact angle

- very wear resistant against abrasion

- Mechanical or magnetic mounting

- Noise reducing

KALIMPACT KALMETAL:

- Plates

- Very high impact energy

- flat and steep impact angle

- wear resistant against abrasion

- mechanical fastening

- Noise reducing

KALIMPACT ABRESIST:

- Plates

- Low impact energy

- flat impact angle

- very wear resistant against abrasion

- Mechanical or magnetic mounting

- Noise reducing